STG Block Adhesive

Category: STG Block Adhesive

Description

Download PDF file Introduction to STG block adhesive

Dry mortar

Using various types of construction mortar is very common and essential in building construction. Despite the invention of different materials and supplies, a suitable substitute has not yet been provided for some of the applications of mortar. From ancient times to the present, various types of mortar have always been used for building and external walls, such as mortar for joining bricks, mortar for plastering internal walls, and tiles and ceramics on floors, walls, and ceilings, sealing and insulation, etc.

The industry for producing mortar for the above-mentioned tasks has faced challenges, such as production, which has always been a major concern in constructing residential buildings. This includes accurately mixing materials to obtain the right mortar, controlling the quality of necessary materials, ensuring the strength and durability of the materials, training skilled personnel for using and applying the materials, transporting and storing materials during the work, managing the mortar after preparation, handling the bulk of materials needed, disposing of excess after construction completion, and moving and using these materials in the building. During the 1960s in Western Europe, the rising demand for industrial building construction and speed of execution led researchers to add polymer materials to solve execution problems and improve its properties. Considering quality and focusing on expanding the application and achieving new chemical additives to solve the issues and drawbacks of traditionally mixed mortars in workshops, the dry mortar technology was invented in Western Europe, and it is now increasingly being used in our country as well.

The advantage of using prefabricated dry mortar

The advantages of this type of mortar can be mentioned as follows:

Diversity products by various grades

Constancy of formula in the production process, due to the combination of materials based on exact weight •No needs for skilled workers to produce mortar

High Speed in preparation, just by adding a certain amount of water

Strength, high quality, beauty, compatible with a variety of construction materials such as

(HEBELEX Concrete), bricks, ceramics, tiles and etc.

Ease in transportation and taking up less space in the site

Ease in storage for using in the next projects

Environment friendly

Lightweight block

High resistance to moisture, shrinkage cracking, termites and other insects, acid rain, heat and cold fluctuations and many other environmental and influential parameters.

Consumption in desired and required sizes.

The ability to absorb the incoming forces and transfer them to the subordinate sector

Shrinkage without retracting

Reducing Human Error

Reducing Implementation Cost

Saving time and speeding up building construction

High Grip Speed

Very good smoothness and no need for any additives except water

High Pressure and Tension Tolerance

Saving cement consumption.

Excellent adhesion to building materials, reducing the dead load of the building

One of the important features of this product is its impermeability to water and its adhesion.

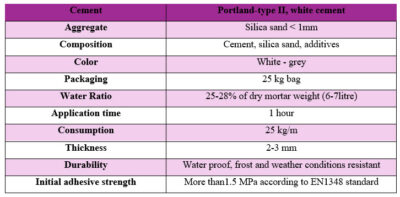

STG Block Adhesive

STG block Adhesive is a thin bed mortar with high strength attributes for quick & firm laying of STG blocks.

Reviews (0)

Be the first to review “STG Block Adhesive” Cancel reply

Reviews

There are no reviews yet.